West Elm-Inspired DIY Side Table

Last weekend, one of my favourite home accounts shared a round up of their favourite bedside table options and in their list was the most stunning West Elm fluted side table I ever did see. I have been looking for a cute little side table to sit between our big front window and our couch, but it has never been enough of a priority that I am willing to spend a few hundred dollars on it. When I saw this adorable little table, my mind began to wander with the possibility of creating a DIY version at a fraction of the purchase price. I’m going to share with you exactly how I did that.

I want to first say that I’m not one to always choose DIY over purchasing something. Cost is one factor in the big picture of curating your home. I truly believe that there is a time and place to spend on the home pieces you love. The original version of this table is beautiful and handcrafted and I’m sure well worth the price point, but in this particular instance, I was looking for a table that was a relatively small size and was eager for a quick and easy project. This table dupe hit all those notes.

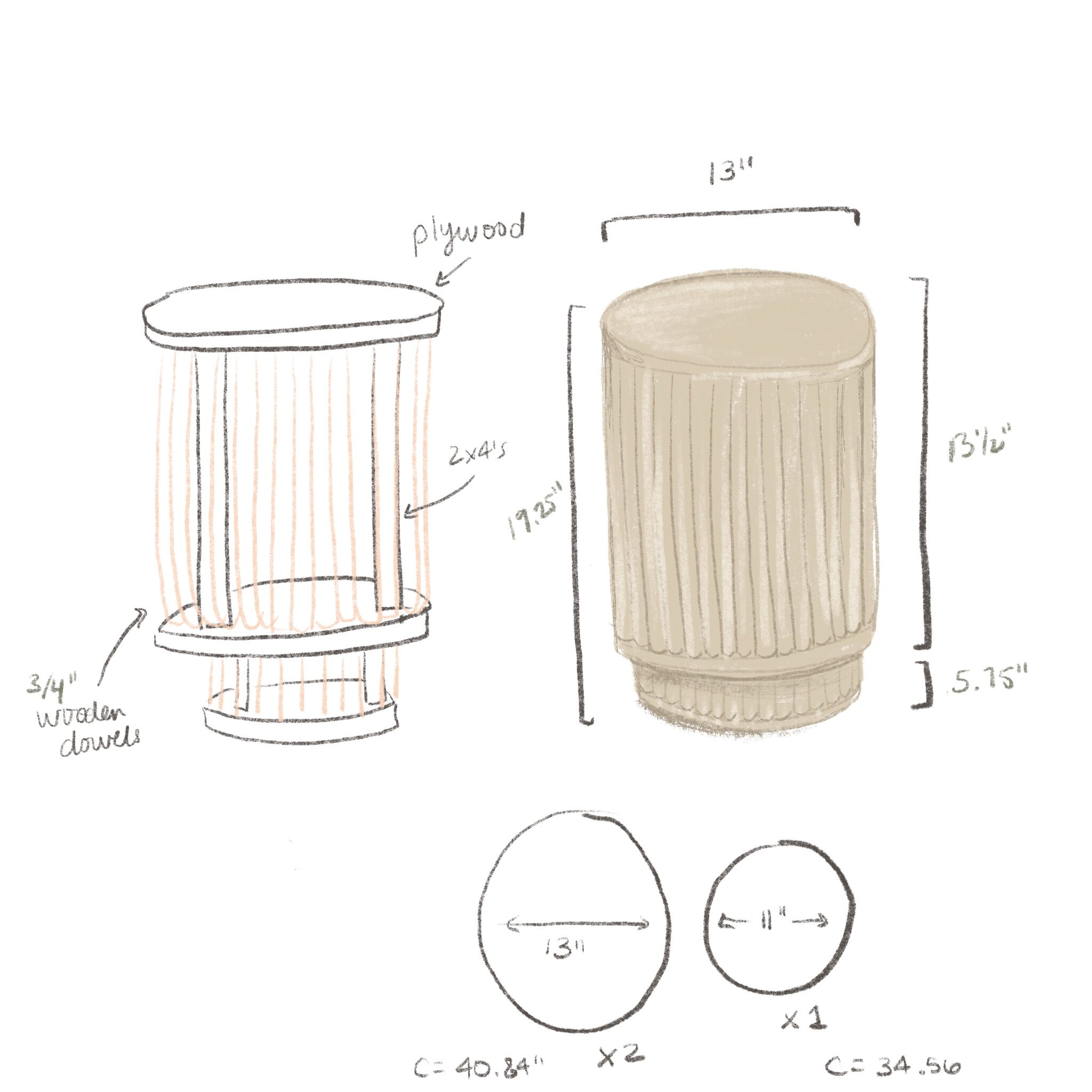

I shared a full video tutorial on our YouTube channel, but I’ll summarize the general process here too. To start, I cut three circles out of some scrap 3/4” plywood - one was roughly 11” in diameter and two were roughly 13” in diameter. I added three brace pieces to each tier using some scrap pieces of 2x4’s. For the bottom recessed portion, I used 5” supports and for the top portion, I used 12” supports. Before attaching the top and bottom pieces together, I added the dowel flutes to the bottom portion using wood glue and a brad nail from the underside to secure each dowel in place. I then placed the top section on the bottom and adjusted the placement until it was centred on all the flutes before securing it in place with some brad nails.

I placed a few of the dowels in place on the top portion so I could find the proper placement of the top circle. Once I had a general idea about placement, I secured the top circle in place and began to add in the side flutes with 12” dowels. I worked my way around, gluing and nailing each dowel in place as I went. I lined my dowels up flush against each other as well as with the edge of the circle. When I got to the last few flutes, I had to inset a few of the dowels slightly to account for the uneven space that would be left for the last dowel. You could definitely start with a circle size that perfectly fit an even number of dowels, but I didn’t bother planning for this. The result of a few inset dowels is perfectly fine with me.

I had all of the materials on hand to build this table, with exception of the wood dowels. So how did I know how many 3/4” dowels to purchase? I followed this formula:

Circumference of your circle / 0.75 (to account for your 3/4” dowel width) = Number of individual dowels you need

Once you know the number of individual dowels you will need, you can calculate how many cuts you can get out of one purchased length of dowel. For example, my dowels came in 4 foot long pieces, so for the 12” tall top portion of my table, I could get 4 dowels out of one piece of purchased dowel. For the 5” tall bottom portion, I could get 9 dowels out of one piece of purchased dowel. So I could plug those numbers into the following formula:

Number of individual dowels you need / Number of pieces you can get out of one purchased piece of dowel

= Total number of dowels you need to purchase

Just remember to account for both the bottom and the top portions. For my circle diameters and heights, I ended up purchasing 16 pieces of 4 foot long 3/4” dowels. This allowed for some extra, too, in case of any cutting or calculating errors.

Inspiration from West Elm

The original table that inspired this build almost had a stone-like texture. I really wanted to create this similar look on my DIY version, so I used a combination of wood filler and drywall spackle. I filled all the nail holes in the top of the table and worked my way along all the edges of the plywood circles to cover the exposed edges. I added some additional layers of texture to the top of the table and used the corner of my spackle knife to push putty into the grooves of each flute where it sat against the plywood circle. The wood filler created a more porous looking texture, whereas the spackle was more smooth. I really liked the combination of both, which you can see in the aerial view of my table top below.

Once it had dried, I went in with a sanding block in a fine grit to smooth out any rough bits. I wiped off all the dust with a damp cloth to prepare for the next step: caulking all the cracks. I wanted the entire table to look like one solid piece. I used standard caulking between each flute on both the top and bottom portions of the table and used my finger to smooth it out. I also went in with a damp rag to remove any excess caulking to make the entire thing look seamless.

Once the caulking dried, I painted the entire piece using Fusion Minerals furniture paint in the creamy colour called Raw Silk. Like most of the other supplies for this project, I had this paint on hand. I gave it two coats in total, and actually added a bit more texture to the table top with the spackle between coats. Once it was fully painted, I used a dry brush method with a light greige-toned paint (House & Canvas chalk paint in the colour Sandstone). It was very subtle, but I think it made a big difference to add just an extra touch of dimension and stone-like texture.

It took a few steps, but overall, this project was so simple. Since I had most of the supplies on hand, I only had to purchase the wood dowels, which cost me about $75 Canadian dollars. Compared to the original price tag at $239 Canadian dollars, it was well worth the effort. I’m so pleased that it fits perfectly in this little space and I always feel so inspired once I finish creating something with my own two hands.

Would you try this project? If you want to see the full process of this build, pop over to the YouTube tutorial.